Ontario's growing infrastructure and communities depend on a reliable supply of close-to-market aggregate. However, the timeline for bringing a new site online has nearly doubled, growing from 5–7 years to as much as 12 years due to increased red tape, community concerns, and overregulation.

The 2023 Aggregate Supply and Demand Study commissioned by the Ministry of Natural Resources found that critical, close to-market licensed reserves within the Greater Golden Horseshoe (GGH) are dwindling.[AZ1] The GGH – which runs from Haldimand County and Niagara in the South, to Waterloo and Wellington County in the west, to Simcoe County in the North and Peterborough and Northumberland to the East currently accounts for nearly 50 percent of Ontario’s aggregate production.

While consumption in this area has remained relatively consistent over the years, the licensing of replacement reserves has not kept pace with consumption. Over the past decade, the number of pit and quarry licenses and the licensed area have decreased. Additionally, more than two-thirds of licensed reserves supplying the Greater Toronto Area (GTA) are over 35 years old, and many are being depleted quickly.

It is estimated that Ontario will require approximately 4 billion tonnes of aggregate in the next 20 years to meet the province’s ambitious infrastructure plans. Of this, 43% would need to be high-quality material to meet specifications for asphalt and concrete, which equates to 1.72 billion tonnes. An estimated 215 million tonnes of high-quality aggregate are located within 100 km of the GTA.

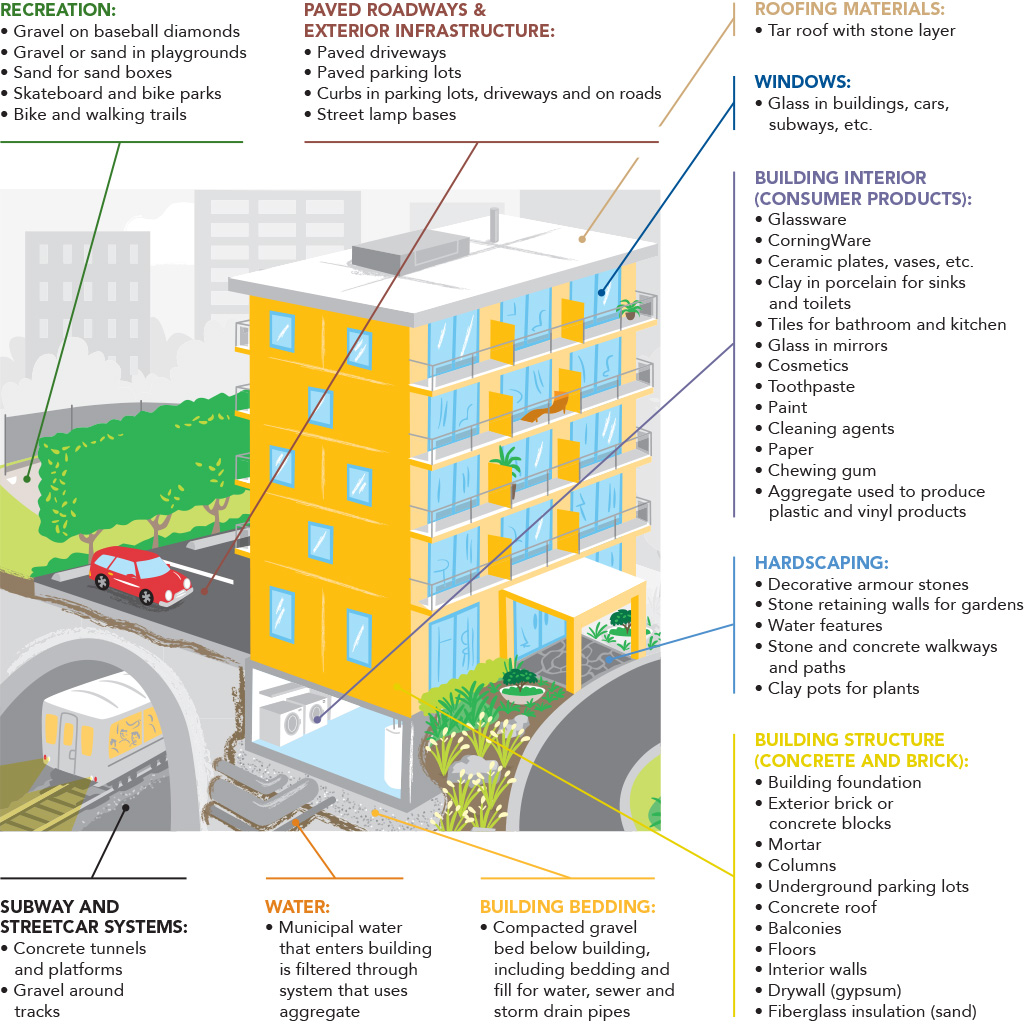

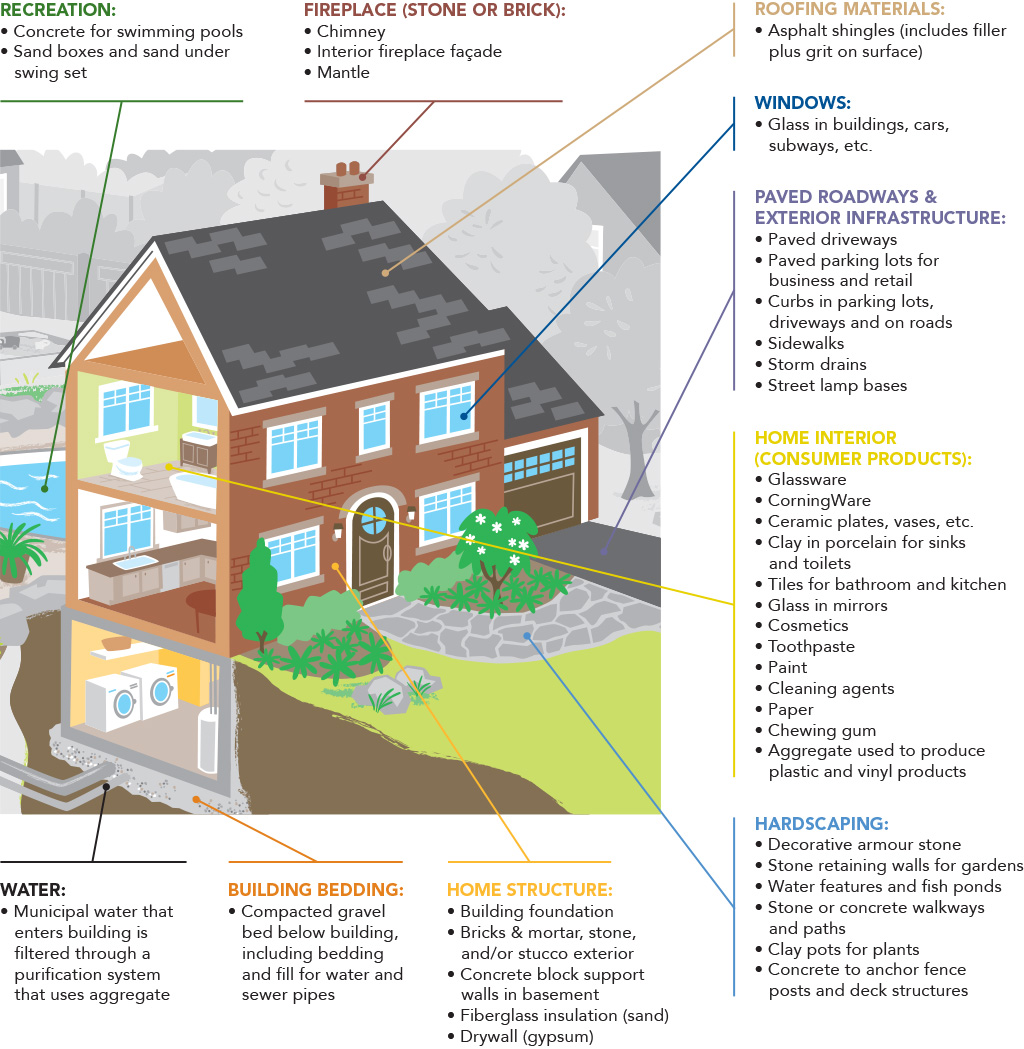

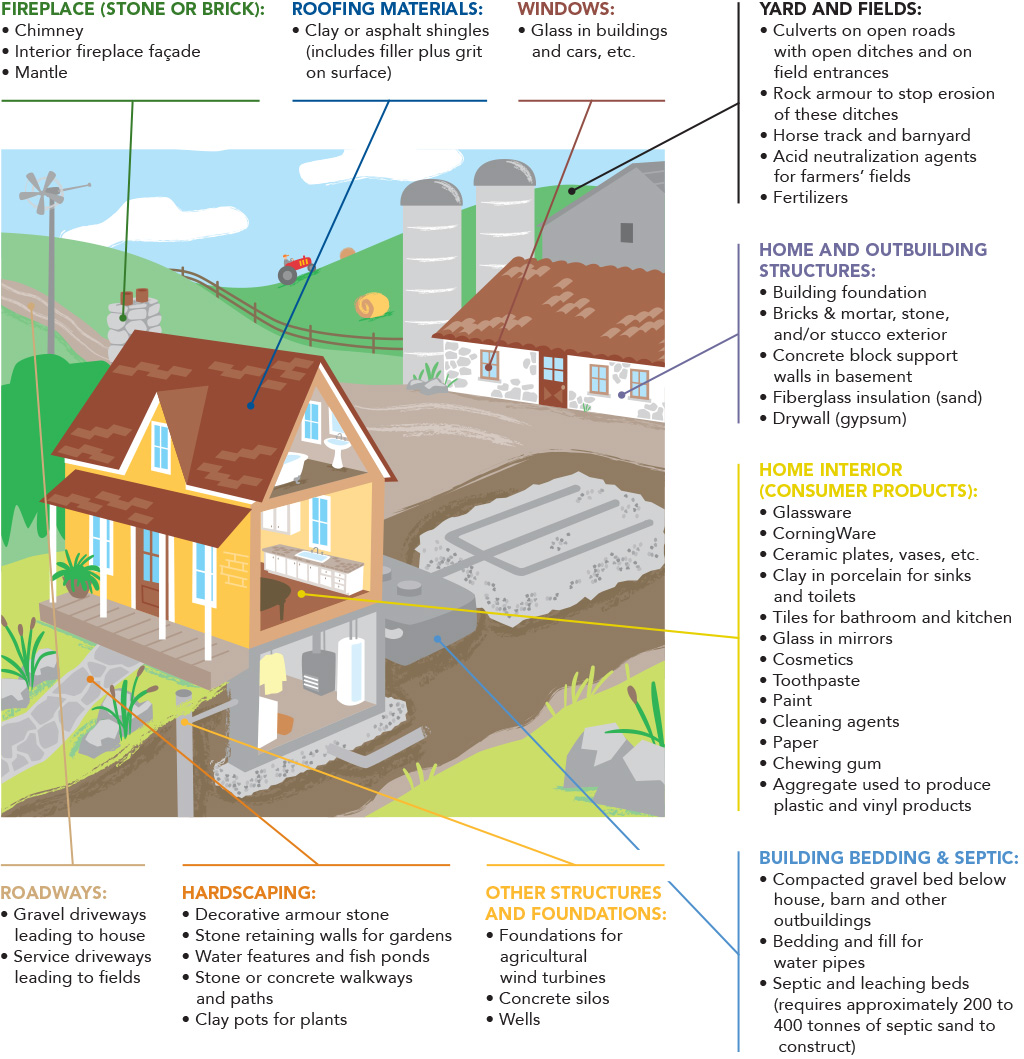

Not all aggregate is the same. For example, 8,000 tonnes of stone, sand and gravel are required per 1 km of a single-lane roadway. While subgrade and subbase materials can vary, asphalt and concrete used for roads demand specific high-quality aggregate. Large infrastructure projects, such as the Trafalgar Memorial Hospital, require about 300,000 tonnes of aggregate, most of which is concrete, made with high-quality aggregate.

So where is the high-quality aggregate going to come from?

The study confirms that Ontario’s close-to-market aggregate resources are under strain – both in terms of quality and quantity. To be clear, there is close-to-market aggregate resources in the ground, but new policies need to be put in place to access those vital resources.

OSSGA is dedicated to addressing these challenges by collaborating with all stakeholders—including governments, municipalities, Indigenous Communities, and residents—to streamline the process. Our commitment remains steadfast: ensuring timely access to aggregate while upholding the industry's highest standards for environmental sustainability, community engagement, and responsible resource management.